News | Articles

Biosakura in the News, Latest Publications, Articles, and Blogs.

Bio-mass technology

The word “sustainability”, we recently hear this word often when we discuss about environmental issue.

NANO-SAKURA recognize this word, as controlling resource consumption and its accompanying effect to the environment appropriately.

As a result, we believe that standard of living of human beings can be maintained in a long term. Therefore, we continue to make an effort to carry out that concept.

1. Nano Sakura Technology

First of all, the main concept of NANO-SAKURA is that material is composed of 100 % nature biomass made, no petroleum. In human history, people have been producing and using petroleum based plastic such as polyethylene (PE), polypropylene (PP).

They are very convenient because they are strong, and easy to manufacture mold products with mass production level. In contrast, recently focused biodegradable resins are generally mechanically weak, and difficult to manufacture mold products with mass production level, when compared to petroleum based plastic.

Most of the times, biodegradable resins have less heat durability, lower crystallinity, lower gas barrier properties too compared to petroleum based plastic.

In this regard, we tried to improve the mechanical strength and molding property of biodegradable resin while keeping 100 % nature biomass characteristic, by studying additive, compositing technology.

And with our resin, mass production is possible with normal injection machine and blow machine, with 100 % nature biomass composition. We try to make biodegradable resin materials as environmentally friendly as possible, that is NANO-SAKURA technology.

2. Composite technology with various type of biomass recycle waste

Green Science Alliance Co., Ltd. make composite material with various type of biomass recycle waste such as waste wood, wood powder, bamboo, cassava waste, bagasse, sugarcane waste etc…

Try to utilize all of biomass resources on planet.

3. Starch based biodegradable resin

Green Science Alliance Co., Ltd. not only make composite material, we also make biodegradable resin itself. One of the material is starch based biodegradable resin.

Not to mention this material is also composed of 100 % nature biomass.

Fig. 1: The scientific ecosystem, enriched by open access. Lancaster et al. (2018)

4. 100 % nature biomass based biodegradable resin

Our 100 % nature biomass based biodegradable resin can be used as normal petroleum based plastic. And eventually they will become CO2 and water. In general, this kind of natural resin is very difficult to manufacture molding products in a mass production level, and also weak.

However, we have improved those weakness with our technology. So that these kinds of material can be very good for the environment.

NANO SAKURA can contribute to protect the environment by promoting this type of 100 % nature based biodegradable resin materials.

5. Reducing the bad environmental impact by promoting recycling.

This point needs to confirm experimentally before comes to firm conclusion. So that following is only a speculation. NANO-SAKURA has may have advantage compared to glass fiber and carbon fiber as reinforced material.

Nano cellulose composite material can remake molding products again even after usage while maintaining its strength. Because glass fiber and carbon fiber are not in nano size, they will break into smaller pieces and become mechanically weaker during manufacturing machine process.

In contrast, nano cellulose is nano size already so that strength may not be effected as glass fiber and carbon fiber do.

*Above resin properties are also for the case not only nano cellulose composite with 100 % nature biomass biodegradable resin but also with petroleum based plastic.

6. Reducing the bad environmental impact with nano cellulose original feature compared to glass fiber and carbon fiber as reinforced material.

NANO-SAKURA has one clear big advantage compared to glass fiber and carbon fiber as reinforced material. That is, Nano cellulose is 100 % biodegradable reinforced material. One can make 100 % biodegradable material with this feature.

Composite material property can be improved by mixing with glass fiber and carbon fiber although these materials are not 100% biodegradable and not good for environment. This is why NANO-SAKURA can be highly advanced cutting edge material.

At the moment, we are the only one company who can produce this type of material in the world. With this big feature, Nano Sakura can promote and expand biodegradable resin application.

7. Efficient utilization of biomass natural recyclable resource

We utilize and make composite material with various type of recyclable biomass waste such as waste wood, thinned wood, wood powder, bamboo, rice, cassava waste, bagasse, sugarcane waste, coconut shell etc…

We try not to waste any precious biomass resources and use them efficiently for the environment. This is one of our policy. The quantity of this kind of biomass waste is huge and discarded everyday in the world.

Sometimes it costs money to discard these type of biomass waste. Thus, our action can be even economically friendly in some cases.

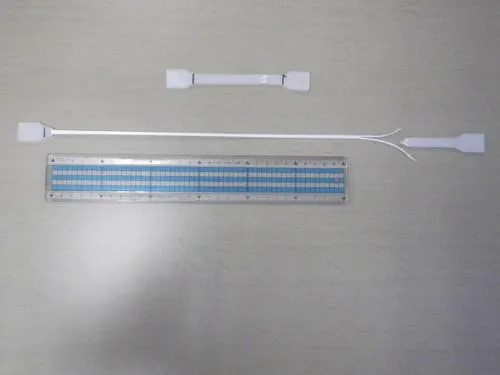

Fig. 2: Photo courtesy of under a CC license.

8. Possible material to solve marine microplastic pollution problem.

Ultimate goal is to make 100 % biodegradable NANO-SAKURA in the ocean. Plastic pollution caused by development of mankind with petrochemical based chemistry needs to be changed. Especially marine microplastic pollution problem is very serious problem caused by human beings.

Marine microplastic pollution is destroying the ecology system and nature. Therefore, it urgently needs to be solved in the world. Precisely, biodegradable resin has some grades and some biodegradable resin can be decomposed in the soil, but not in the ocean.

Fig. 3: Stand aside, CERN - it's a new age of accelerating science! Photo courtesy of under a CC license.

The best biodegradable plastic is the one which can decompose in the marine environment. We, Green Science Alliance is under intensive research to develop such great material.

References

ASAPbio, Preprint Resource Center: https://asapbio.org/preprint-info

ASAPbio, Preprints and Rapid Communication of COVID-19 research: https://asapbio.org/preprints-and-covid-19

Ettinger CL, Sadanandappa MK, Görgülü K, Coghlan KL, Hallenbeck KK, Puebla I (2022) A guide to preprinting for early-career researchers. Biol Open. https://doi.org/10.1242/bio.059310

Fraser N, Mayr P, Peters I (2021) Motivations, concerns and selection biases when posting preprints: a survey of bioRxiv authors. bioRxiv. https://doi.org/10.1101/2021.09.07.459259

Sarabipour S, Debat HJ, Emmott E, Burgess SJ, Schwessinger B, Hensel Z (2019) On the value of preprints: An early career researcher perspective. PLoS Biol. https://doi.org/10.1371/journal.pbio.3000151

Sever R, Roeder T, Hindle S, Sussman L, Black K-J, Argentine J, Manos W, Inglis JR (2019) bioRxiv: the preprint server for biology. bioRxiv. https://doi.org/10.1101/833400

Stern BM, O’Shea EK (2019) A proposal for the future of scientific publishing in the life sciences. PLoS Biol. https://doi.org/10.1371/journal.pbio.3000116

Featured Publications

Green Science Alliance Co., Ltd. Has Developed Nano Cellulose And Biodegradable Resin Composite Material...

PlasticsNet, a VertMarket Markeplace for Industry Professionals

Development of Nano Cellulose in Various Type of Vegetable Oil, With 100 % Nature Biomass Composition

MetalsNews.com

Biodegradable Resin Beads, Scrub to Replace Micro Plastic Beads and More...

Business Insider Article

Green Science Alliance Succeeded in Artificial Photosynthesis

Energy News Wire

Green Science Alliance develops plant, UV light curable hard coat material

Bioenergy News

Green Science Alliance Developed Artificial Photosynthesis Textile Sheet to Make Formic Acid From CO2

Yahoo life

Green Science Alliance creates 100% biomass biodegradable plastic

Biomass Magazine

Green Science Alliance licenses plastic recycling technology from Fukuoka University

NS Packaging

BIOMASS NATURE DERIVED CELLULOSE BASE BIODEGRADABLE RESIN MATERIALS

The Ritz Herald

Dr. Mori Celebrated for Dedication in Industrial Research and Development

24-7 Press Release

World’s first biodegradable, ethical nail tips released In Japan

Zenbird

Green Science Alliance Develops Eco-Friendly Nail Polish Formula

Beauty Packaging

New Technology to Maintain the Mechanical Strength of Plastic Waste

Global Recycling

100% Nature Biomass Based Biodegradable Resin: Nano Sakura

UN Climate Technology Centre & Network

Green Science Alliance Developed 3D Printable Biodegradable Plastic (PLA) / Hydroxyapatite Composite Material ...

PR Newswire

Biosakura, a Green Science Alliance Co. Ltd. (Fuji Pigment USA Inc. Group Company). Based out of Cambridge, Massachusetts providing solutions to today's toughest environmental challenges.

Connect With Us

+81-90-8528-2305

www.biosakura.com

82 Wendell Ave. Ste 100

Pittsfield, MA 01201

USA

Copyright 2022 Fuji Pigment USA Inc. All Right Reserved

Made possible by The Viking Stack.