News | Articles

Biosakura in the News, Latest Publications, Articles, and Blogs.

world's first! GS Alliance develops 100% natural biomass-based biodegradable plastic made from wood and stone itself using natural deep eutectic solvent

Translated from Japanese. Originally published 2/2/2022.

Article: https://www.newsweekjapan.jp/press-release/2022/02/gs100.php

World's first! GS Alliance develops 100% natural biomass-based biodegradable plastic made from wood and stone itself using natural deep eutectic solvent

GS Alliance Co., Ltd. (Location: Kawanishi City, Hyogo Prefecture, Representative Director: Dr. Ryohei Mori (Engineering)), a chemical company that researches and develops cutting-edge materials for the environment and energy fields to build a carbon-free and carbon-neutral society , developed a 100% natural biomass-based biodegradable plastic made from wood and stone itself using a natural deep eutectic solvent.

100% natural biomass thermoplastic resin material made by dissolving wood and cedar powder itself

Environmental problems such as global warming, environmental pollution and deforestation caused by the population explosion are serious problems, and plastic pollution is also destroying ecosystems. It's becoming a devastating level to destroy. It is said that by 2050, the amount of plastic waste floating in the sea may exceed the amount of fish, and there are reports that microplastics and nanoplastics from the atmosphere are already entering the human body.

Strictly speaking, plastics are called thermoplastic resins. They are melted by applying heat, and in the melted state, they are put into a molding machine and molded into various shapes to become products. In other words, the definition of plastic (thermoplastic resin) is that it can be molded into various shapes by applying heat. Before molding with a molding machine, it is in a granular state of 1 to several millimeters called resin pellets. Recently, various biodegradable plastics have been produced by companies in Japan and overseas, and are gradually being put into practical use. not. These biodegradable plastics are made from petroleum or from biomass such as corn and sugar cane, but they have the problem of competing with human food.

Cellulose is an ideal biomass that does not compete with human food, but there are challenges such as the difficulty of converting cellulose into a thermoplastic resin without using any petroleum-derived additives.

Dr. Ryohei Mori (Engineering) of GS Alliance has recently developed a thermoplastic material from wood itself using the deep eutectic solvent developed by the company, especially the natural deep eutectic solvent with 100% natural composition. . Trees and plants are mainly composed of three components, cellulose, lignin, and hemicellulose, and these components are swollen, finely dispersed, dissolved, and processed into thermoplastic materials with a deep eutectic solvent. increase. In a similar way, all terrestrial plants, including wood, waste wood, waste plants, seaweed, waste paper, pulp and other natural organic resources can be used as raw materials.

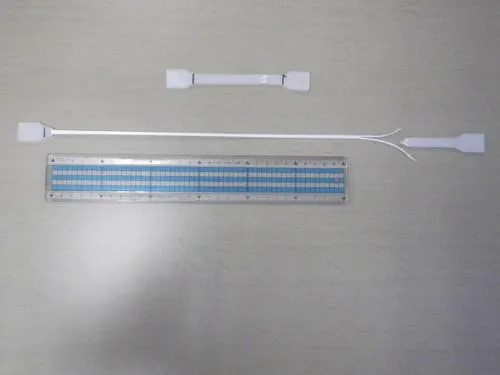

There have been reports of research at overseas universities on the use of a deep eutectic solvent to create a resin-like material from wood, but no thermoplastic material that can be molded with an extruder has been made. . As in the case of the GS Alliance, wood treated with a deep eutectic solvent is compounded with stone-derived materials such as talc, processed with a twin-screw extruder, pelletized into thermoplastic resin, and molded. This is the first time in the world that it was developed as a thermoplastic resin. This result has made it possible to put it into practical use in the true sense of the word.

In addition to wood and stone, other ingredients, including natural deep eutectic solvents, are also environmentally friendly ingredients that are already common in human society. Made from 100% natural ingredients, it is the ultimate eco-friendly material. Furthermore, not only wood and stone, but also all other constituent materials are relatively inexpensive, and low costs can be expected during mass production. However, this material alone has problems such as being slightly weak against water and mechanical strength. However, in order to solve this problem, we have also confirmed that by combining it with other natural biomass-based biodegradable resins, we can improve water resistance and mechanical strength while maintaining 100% natural biomass components.

In the future, we will analyze this innovative new material, further improve the resin characteristics, and at the same time start sample work in Japan and overseas.

Company Profile

Trade name: GS Alliance Co. , Ltd.

Representative: Dr. Ryohei Mori (Engineering), Representative Director

Head office location: 2-22-11 Obana, Kawanishi City, Hyogo Prefecture 666-0015

Business description: Decarbonization, environment and energy to tackle SDGs issues Research and development of cutting-edge materials and

technologies in the field (

Adopted in 2020 for UNOPS GIC KOBE, a United Nations start-up company support program)

URL: https://www.gsalliance.co.jp/

Featured Publications

Green Science Alliance Co., Ltd. Has Developed Nano Cellulose And Biodegradable Resin Composite Material...

PlasticsNet, a VertMarket Markeplace for Industry Professionals

Development of Nano Cellulose in Various Type of Vegetable Oil, With 100 % Nature Biomass Composition

MetalsNews.com

Biodegradable Resin Beads, Scrub to Replace Micro Plastic Beads and More...

Business Insider Article

Green Science Alliance Succeeded in Artificial Photosynthesis

Energy News Wire

Green Science Alliance develops plant, UV light curable hard coat material

Bioenergy News

Green Science Alliance Developed Artificial Photosynthesis Textile Sheet to Make Formic Acid From CO2

Yahoo life

Green Science Alliance creates 100% biomass biodegradable plastic

Biomass Magazine

Green Science Alliance licenses plastic recycling technology from Fukuoka University

NS Packaging

BIOMASS NATURE DERIVED CELLULOSE BASE BIODEGRADABLE RESIN MATERIALS

The Ritz Herald

Dr. Mori Celebrated for Dedication in Industrial Research and Development

24-7 Press Release

World’s first biodegradable, ethical nail tips released In Japan

Zenbird

Green Science Alliance Develops Eco-Friendly Nail Polish Formula

Beauty Packaging

New Technology to Maintain the Mechanical Strength of Plastic Waste

Global Recycling

100% Nature Biomass Based Biodegradable Resin: Nano Sakura

UN Climate Technology Centre & Network

Green Science Alliance Developed 3D Printable Biodegradable Plastic (PLA) / Hydroxyapatite Composite Material ...

PR Newswire

Biosakura, a Green Science Alliance Co. Ltd. (Fuji Pigment USA Inc. Group Company). Based out of Cambridge, Massachusetts providing solutions to today's toughest environmental challenges.

Connect With Us

+81-90-8528-2305

www.biosakura.com

82 Wendell Ave. Ste 100

Pittsfield, MA 01201

USA

Copyright 2022 Fuji Pigment USA Inc. All Right Reserved

Made possible by The Viking Stack.